Built for the

new normal

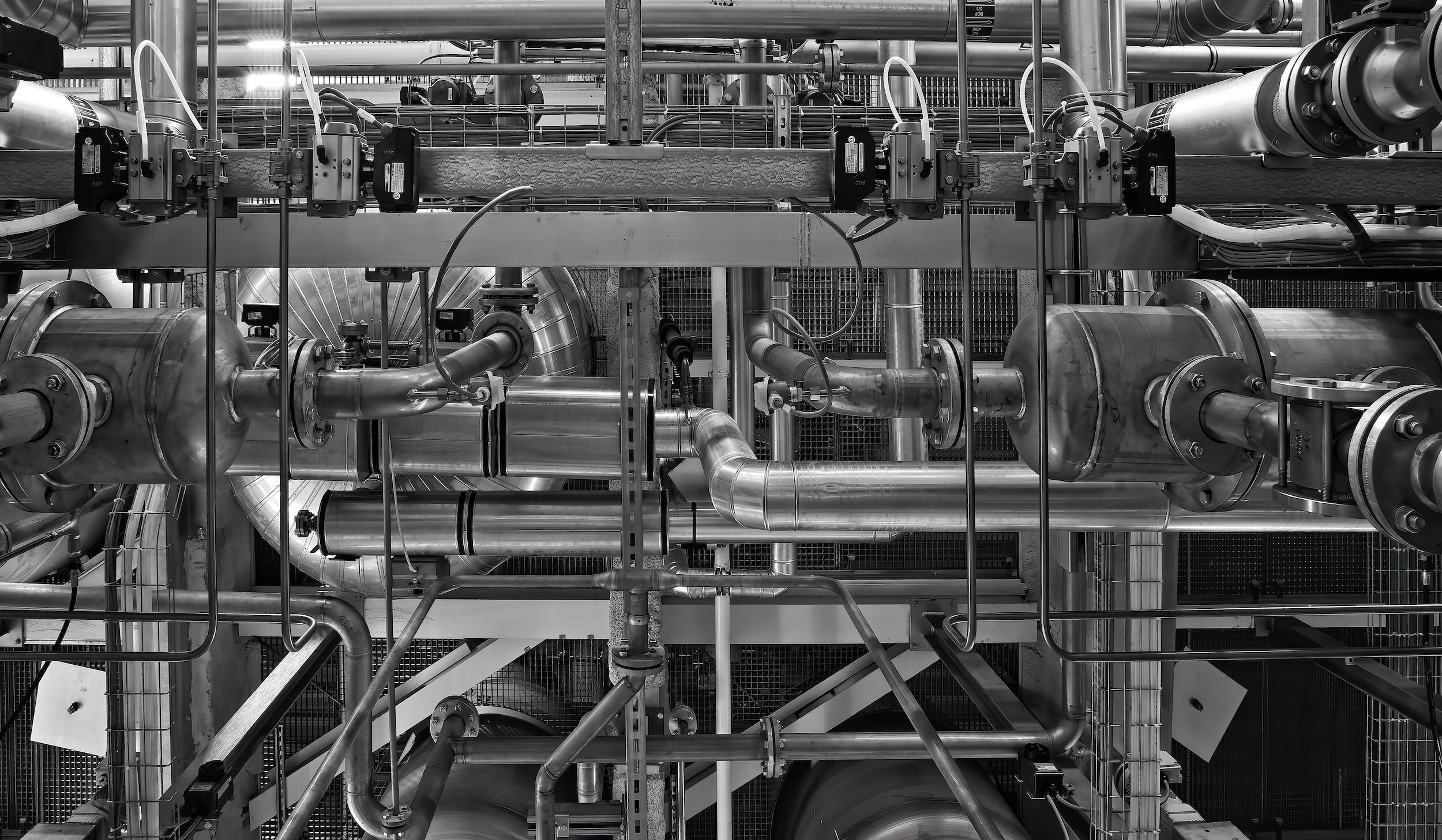

There’s zero room for error in precision manufacturing. Customers want more and they want it now. Product runs are fast. Orders are complex. Margins are lower than ever. Fuel costs a fortune. Parts cost a fortune. The lathe is down again. There’s no free lunch. The supply chain sucks. The labor market sucks. Everything’s on backorder. Perfect is the bare minimum.

Enter Airventory.

Airventory was born to solve an urgent problem: My team was wasting hours tracking assets.

Spreadsheets weren’t cutting it. Third-party solutions were too expensive or too tricky to implement. And the longer we went without real-time hardware visibility, the more we bled money, lost bids, and fell behind.

Like so many small manufacturers, my shop was buckling under rising production and labor costs and increasingly complex customer orders. The days of high-volume, low-mix orders were far behind us, and the only way for us to compete in a changing market was to adopt an agile workflow, and to do it quickly. We needed faster turnaround of our machines, cross-team visibility into our production capacity, and intelligent procurement systems that knew what needed fixing, replacing, or refitting long before it could become a problem.

The challenge was clear. I needed to transform a small, legacy shop into a dynamic, nimble operation without spending a fortune, shutting down production, or stoking resistance on my staff. I needed something that worked, and I needed it right now.

Airventory was the simple, powerful solution we needed. I designed it to work with the shop, tools, and staff you already have, so you get high-tech production velocity without the hassle or the price tag.

Efficient. Effective. Affordable.

That’s Airventory.

Mike Budzinski,

Co-Founder

David Jones,

Co-Founder